Hemp Panel System offers prefabricated exterior and interior walls filled with hempcrete.

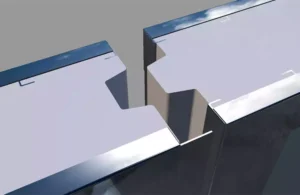

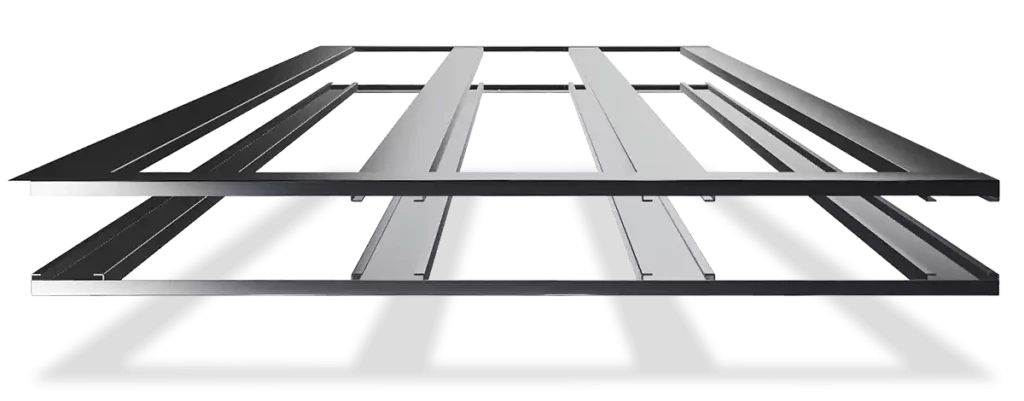

All load bearing, ultra-energy efficient, meeting the toughest codes. Hemp Panel System patented hemp and EPS bonding technology results in the highest strength-to-weight ratio of any other type of SIP (Structural Insulated Panel) requiring no sheathing for its stability. Our composite panels are made of a patented bonding technology with a complete thermal break between the interior and exterior. They are exceptionally strong, light, and energy-efficient. Every panel provides structure, vapor barrier, insulation, and sheathing — all in one efficient labor-saving step.

The project is pre-manufactured in our facility and arrives on-site ready for assembly like big building blocks. Every project includes a complete set of shop drawings signed and sealed by the project’s Engineer and Architect.

Once tracks are in place, an average installer will install about 4 panels every hour, with a very fast learning curve (4 hours typical). With an average size of 40 sqf per panel, that is 160 sqf of wall per hour. More so, since the panel arrives on site with an electrical chase, and a complete thermal break, and does not require OSB or other sheathing, with one hour of labor you have 160 sqf of structure, 160 sqf of sheathing, 160 sqf of vapor barrier, and 160 sqf of insulation all achieved by one person. Hemp Panel System enables 1 tradesmen to do the work of 4 in one simple step. The result is tremendous time savings, and that translates to cost savings!

- Labor from 4 to one

- Framing time reduced by half

- Cost of labor less than a third of traditional materials

- Reduced Materials and shipping coordination

- Eliminates the need for dumpsters

- Panels weigh about 45Lb – eliminating crane rental

There are more savings in the long term:

A complete thermal envelope with an effective thermal performance of R28-61, with a complete thermal break, reduces energy bills by up to 75%. In addition, high air tightness and significantly less air leaks helps reduce the initial size of the mechanical system by over 50%. The panel is a non-biodegradable material and will keep its thermal performance over time. In addition, it will not develop mold, mildew, fungus, or any allergens. Studies show savings of up to 12% in long-term maintenance of commercial buildings. The system is maximized when it is used holistically. Then design coordination is quicker, details align and it becomes a one-stop-shop. One invoice, one shipping company, one draw, one installer, one engineer and architect. Slick, quick and efficient!

The combined advantages of lightweight panels, ultra-high insulating properties, and strength makes Hemp Panel System panels ideal for cold storage applications, mid-rise, hotels, assisted living facilities, and homes. Hemp Panel System panels can support multi-story loads.

Stronger. Tougher. Safer.

Our 16-gauge panels are maintenance-free, pest-resistant, fire-resistant, earthquake-resistant, and wind-resistant up to 220MPH. We meet and exceed Miami-Dade County hurricane-resistance standards.

- True load bearing system up to 15,000 PLF

- 20,000 PLF LRFD compression

- 120 PSF transverse at L/180 (12ft span)

- Panels are smoke- and fire-treated for noncombustible assembly, and meet the lowest smoke and flame spread code standards

- Meets High Velocity Hurricane Zone (HVHZ) requirements

- ASHRAE 90.1 compliant and completely thermally broken: no need for exterior insulation

- CFC and HCFC free, no off-gassing

While some building projects use open-cell materials, our closed-cell technology eliminates moisture absorption, increases structural strength, reduces air infiltration, lowers perm rate, and reduces sound transfer. All performing better than most SIP and to open-cell methods. In particular, when temperature declines, open cell materials contract, meaning their energy efficiency is negatively impacted. With our closed-cell technology, thermal performance is immune to temperature cycles, allowing Hemp Panel System to maintain effective R-Values for its entire lifetime: Roughly 400 years! Hemp Panel System uses M77B EPS type which does not ignite. In addition, closed-cell technology is a stronger structure making it a good application for impact absorption, seismic design, hurricane, and ballistic applications. And of course our low perm ratio, even when exposed in the ground.

- Low perm

- Constant thermal performance (no thermal drifting)

- Strong and stable

- Continuous support for the sheathing

- Higher STC acoustic performance

What is the STC rating of wood framing? – none. There are gaps of 16” between the studs allowing the sound to flow freely. The Sound Transmittance Coefficient [STC] is dependent upon the density and type of insulation in-between the studs. In other words, in conventional framing, the thermal insulation is dictating the sound insulation. Hemp Panel System panels are designed to provide high acoustic performance independently from thermal performance. While wood studs are better at low frequency, consider that:

- Hemp Panel System is better than wood for approximately 90% of the frequency range.

- Hemp Panel System is excellent in high frequencies.

- Most noises in homes are in the high frequency range.

A standard 5.5″ wall with one layer of sheathing 5/8″ thick on both sides of the panel will provide acoustic performance in excess of STC 45. Increasing the EPS density to 1.5 pcf will increase the acoustical performance over STC 50.

If you are a developer 2 things drive your business: Time and money.

Short timeline from permit to occupancy means lower soft costs, lower carrying costs of financing, faster return of interest payments. Faster occupancy means higher revenue and a faster return. Faster return means higher ROI and better cap-rate and higher profit. We all know that. But how do we get there?

By providing a one stop shop, pre-manufactured panels system, for the entire building envelope, from foundation to roof, and reducing labor on site from four trades to one trade, construction time is reduced by 50%. That means is occupancy and collecting revenue much faster than traditional construction.

Utilizing high thermal performance of building envelope, reduces energy loss and allows downsize over 60% of HVAC equipment. In addition, eliminate ducts, hanging labor etc. typical three-ton unit is replaced by a 15,000 BTU multi zone mini-split. HVAC reduces over $3,500 per unit.

- Eliminating ducts, allows to reduce ceiling height by roughly one foot per floor. On a typical three-story building, reducing three-foot height of the entire building, saves easily over $100,000. Floor and reduce energy bills by up to 75%.

- A smaller HVAC system and a high performing thermal envelope significantly reduces energy bills. Other study cases show reduction of 75% of energy bill and Reduction of maintenance cost by 15%

- Eliminate the cost of sheathing over the entire building, eliminate the cost of insulation and weather barrier over the entire building

- Eliminate crane, reduce scaffolding time to a third, reduce dumpsters to a quarter

It all boils down to the bottom line of the developer. Completion of project by up half the time, reduction of over 50% of labor and huge savings on value engineering. On average the total construction budget is reduced by 15-24%. Hands down, Hemp Panel System is the solution.

Prefabricated tailor-made panels, for your project allows you to begin production ahead of time and stage it as needed shortening timeline of construction. All panels arrive on site bundled and marked ready for assembly, drop in place, with an average assembly rate of 160sqf per hr. In otherwords, half of the construction time comparing to conventional method.

All panels come ready with all rough openings, including an electrical chase and all required accessories (headers, jacks, kings, plates, screws etc.) reducing labor and saving time on site.

What about electrical and plumbing?

Hemp Panel System is providing the entire building envelope from one prefabricated facility. Saving costs of designers, shipping, coordination, and labor. Panels are effectively performing as the structure, sheathing, vapor barrier and insulation all in one panel, reducing 4 trades into 1. Eliminating dumpsters and excessive martial from the construction site. Saving materials.

Hemp Panel System began manufacturing panels in 1970 in Radford VA. We manufacture panels for multifamily, mid-rise, and commercial. We completed over 75,000 projects. We can do your project too. All pre-manufactured assembly ready within your timeline and budget.